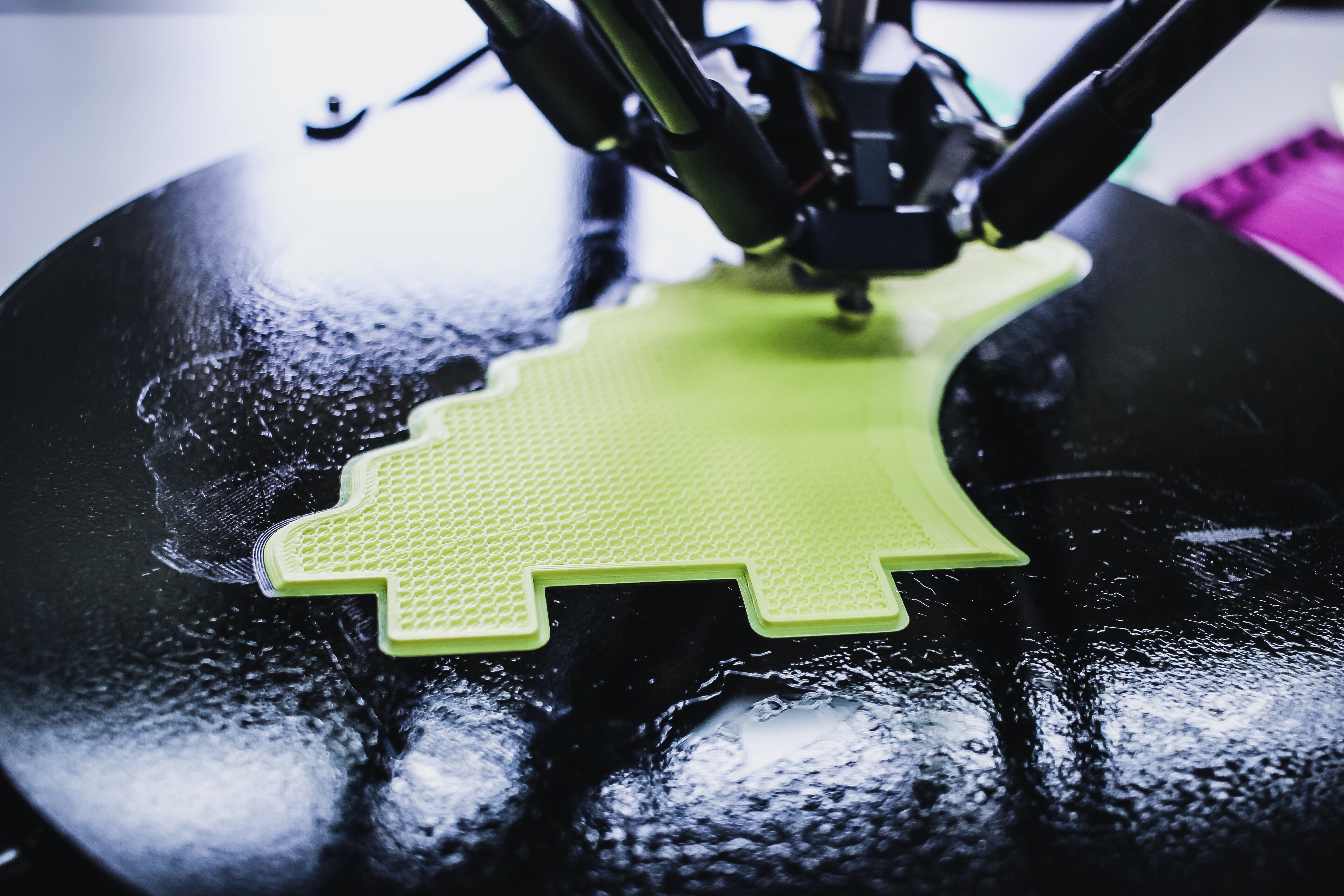

Could 3D Printing Lead to Distributed Manufacturing? 16/07/2019

A team of researchers from the University of Lisbon and the Carnegie Mellon University’s Department of Engineering and Public Policy (EPP) investigated how additive manufacturing (AM) could contribute to distributed manufacturing. They examined whether AM will disrupt this central model, specifically in the context of spare parts for the aviation industry, where being able to quickly print parts instead of stockpiling them would be attractive.

The team includes Parth Vaishnav, an assistant research professor in EPP and member of the Next Manufacturing Center, Erica Fuchs, a professor in EPP; Joana Mendonça, professor at the University of Lisbon and member of IN+; Jaime Bonnín Roca, former Ph.D. student in EPP and now an assistant professor of innovation and entrepreneurship at Eindhoven University of Technology in the Netherlands; and Ria Laureijs, a Ph.D. student in EPP.

The team points out that the discussion around AM’s potential role in changing manufacturing practice have been exaggerated in some contexts, especially if one considers its economics. In manufacturing, a company chooses whether to site its factories nearer or farther from their markets and customers, which affects shipping and stockpiling costs. While decentralized AM close to where products are needed may reduce the need to carry inventory, the very expensive machines that are sometimes needed to process parts after they emerge from 3D printing may still favor centralized manufacturing.

The team concluded that decentralizing manufacturing would make economic sense for non-critical spare parts with combined annual production volumes in the 10,000s. If the 3D printers improved enough that post-processing steps could be eliminated, then decentralized manufacturing would be economical at lower volumes-but these would still be in the tens of thousands. Cheaper machines would also mean that labor will become a larger proportion of total costs. This could be mitigated by automating the machines, which in turn could affect employment.